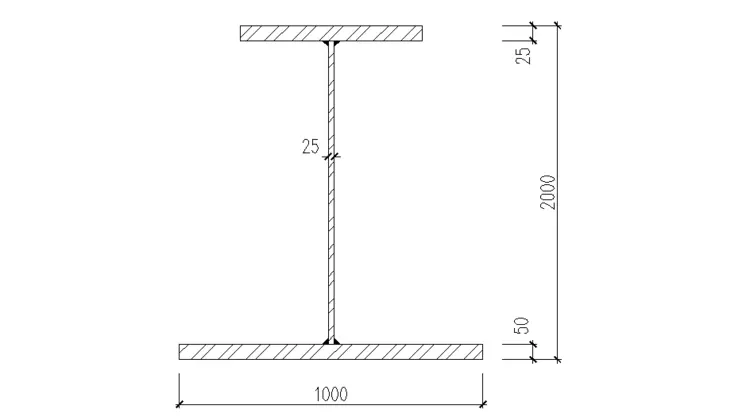

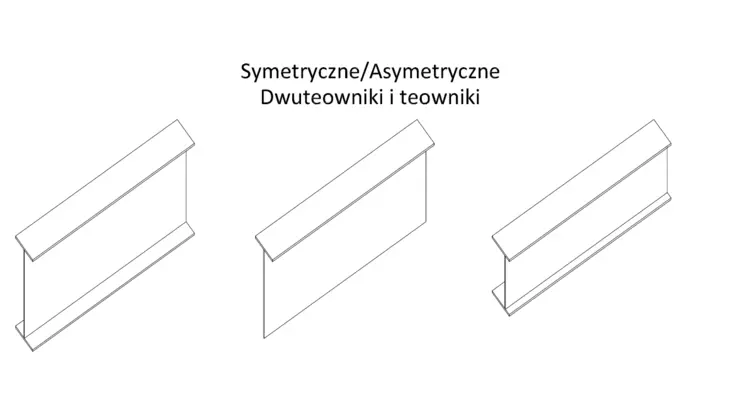

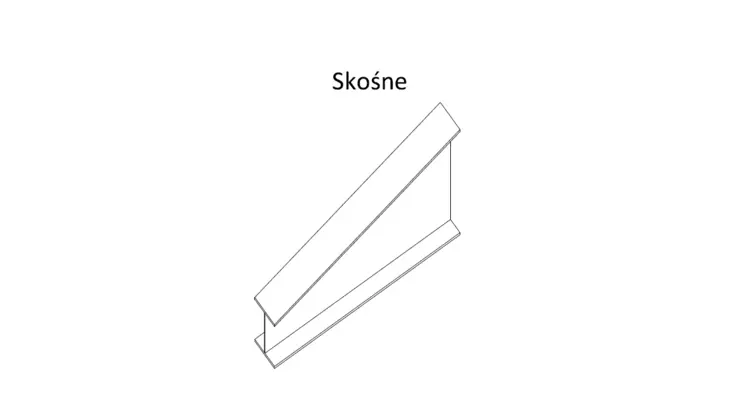

What are plate girders

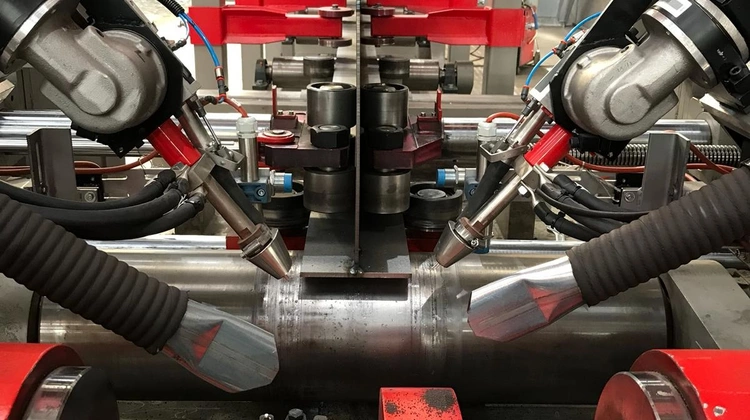

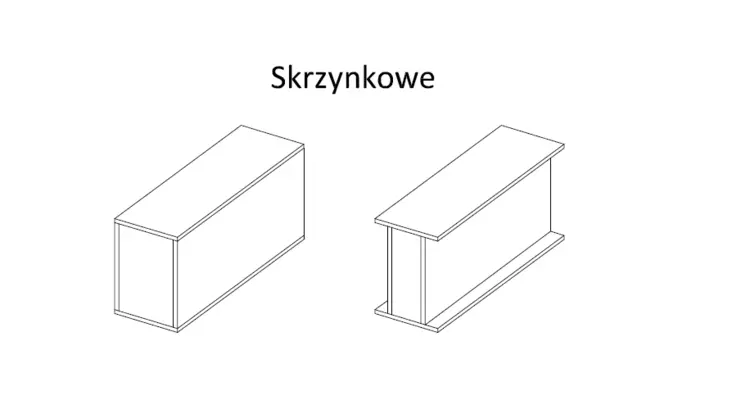

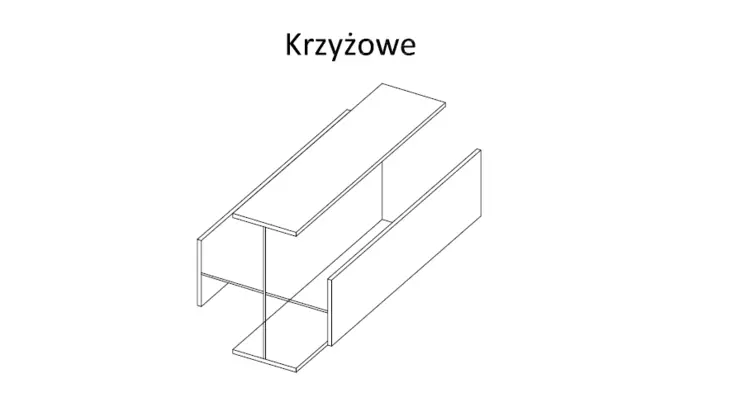

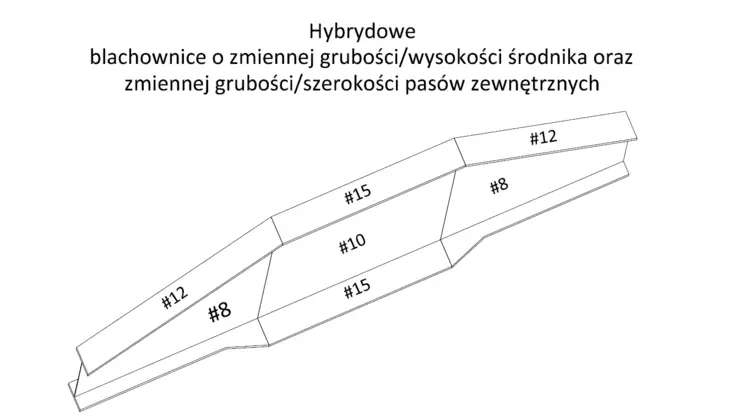

Plate girders have a characteristic structure, type of materials used and method of manufacture. They consist of pieces of sheet metal welded together. The production of plate girders has become more widespread thanks to the development of computer programs, mechanization and production automation as well as technology related to the element shaping process.